-

English (US)

Choose your OTT HydroMet brand and region:

Strictly speaking, even a measuring instrument manufactured to the highest standards still lacks a certain ingredient. Regular calibration of all measurement equipment is the key to maintaining the original performance and accuracy.

We recommend calibration of measurement instruments as a basic rule every two years.

Do you have any questions about our products or do you need advice or an offer for your project?

We offer instrument calibration services for almost all our models and sensors of environmental measurement equipment, including those for detecting temperature, relative humidity, air pressure, and flow.

Our team of qualified technicians, working in our in-house laboratory, ensures that your instruments perform as they should and conform to all relevant manufacturer standards.

We will issue you a detailed calibration certificate outlining the calibration results of your equipment within a few days. All our lab certificates are traceable to national and international standards, specifically ISO:9001. We offer a fast, reliable, and competitive service for all your sensor equipment calibration needs.

In our calibration laboratory, your instruments are calibrated to meet your individual requirements. The calibration is performed in specifically equipped laboratories, including wind tunnels and climate chambers.

Our services cover the entire spectrum of our product range: temperature, relative humidity, air pressure, wind, precipitation, and radiation. These services are operated according to common factory and ISO: 9001 requirements.

Specific delivery times are available on request or by arrangement. For more information about our calibration services, please contact us at met-serviceorder@otthydromet.com.

You can download the certificate here.

Regular calibration of all measurement equipment is the key to maintaining the original performance and accuracy. We recommend calibration of the sensitivity of our radiometers every two years.

The individual sensitivity of a Kipp & Zonen radiometer is determined under the measurement conditions stated on its calibration certificate and is valid at the date of first use. If the radiometer is carefully stored in dark, warm and dry conditions and desiccant is changed as required, the sensitivity will not change. Many factors affect the measurement uncertainty of a radiometer under varying measurement conditions that differ from the calibration conditions, but the non-reversible effect on sensitivity is mainly caused by exposure to solar radiation. The physical properties of any optical radiometer change due to ultraviolet (UV) radiation affecting diffusers, optical filters, photodiodes, and the black absorber coating of thermopile detectors.

Kipp & Zonen specifies this ageing affect as ‘non-stability (change/year)’ and, in general, it will take about two years to noticeably affect the accuracy of measurements. It is for this reason that Kipp & Zonen recommends you calibrate your radiometers at least once every two years.

However, industrial customers using our products in testing, quality or process control (including solar energy) may have internal QA/QC procedures that require annual calibration. Certain industry standards, such as IEC 61274-1, March 2017 Photovoltaic system performance – Part 1: Monitoring, may also specify a yearly calibration interval.

Factory standard radiometer calibrations always nearby

For your convenience, Kipp & Zonen operates a network of centrally managed calibration facilities around the world that can also offer the most common pyranometer repairs.

Your Advantages Are:

Pyrheliometers, UV radiometers and some specialized products can only be calibrated at the factory.

Which Devices can be Calibrated?

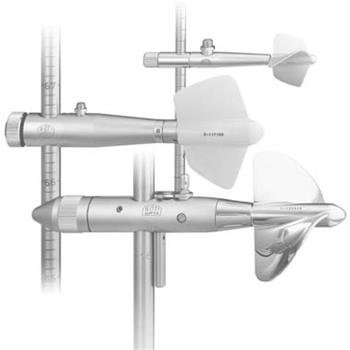

In addition to mechanical current meters, we calibrate magnetic inductive instruments like OTT MF Pro Velocity Sensor. And of course, anyone who still works with the OTT Nautilus will be served too.

The Devices in Detail

What do we offer?

Regular maintenance and calibration of all sensors is recommended at least every 90 days to maintain good quality data.

We offer a full factory performance test & evaluation on Hydrolab Sondes (HL & Series 5) & Surveyor’s (Surveyor 4A & HL).